A bharrachd air an sin, tha feartan eile aig magnets SmCo:

Coileanadh earbsach: Tha magnets SmCo gu math seasmhach an aghaidh demagnetization gan dèanamh earbsach ann an iomadh àrainneachd.

Frith-chreimeadh agus oxidation: Mar thoradh air an ìre ìosal de iarann anns an stuth co-dhèanta, tha deagh sheasamh an aghaidh creimeadh aig magnets SmCo.Eu-coltach ri NdFeB, chan fheum magnets SmCo electroplating.

Seasmhachd teòthachd: Faodaidh SmCo an fheachd magnetach aige a chumail aig teòthachd àrd (249-300 ℃) agus teòthachd glè ìosal (-232 ℃).

Stuthan brisg: Nuair a bhios iad ann an sintering, faodaidh an stuth a bhith brisg, leis gu bheil e brisg agus furasta a sgàineadh, tha crìochan aig a’ ghiollachd, rud nach eil na dòighean giullachd traidiseanta comasach.Ge-tà, faodaidh e a bhith air a ghlanadh, ach a-mhàin ma thèid tòrr fuarachadh a chleachdadh.Tha sin air sgàth gum faod an fhuaradair an cunnart bho theine bho sgàineadh teirmeach agus duslach bleith oxidized a lughdachadh.

Iarrtasan:

1. Àrd-deireadh PM motairean.Mar as trice bidh na motaran PM coitcheann a’ cleachdadh magnets ferrite no magnets NdFeB.Ach ann an àiteachan far a bheil an teòthachd nas àirde na 200 ℃ no gu bheil an torque stàile mòr, chan eil ach motaran SmCo PM comasach.

2. Innealan electroacoustic ann an siostaman glaodhaire àrd-deireadh.

3. Siostam ionnsramaid fìor earbsach.Feumaidh mòran ionnstramaidean a thathas a’ cleachdadh ann an aerospace, itealain, meidigeach agus raointean eile magnets maireannach SmCo a chleachdadh gus dèanamh cinnteach à earbsachd àrd agus sàbhailteachd foirfe.

4. Ann an siostaman radar agus conaltraidh air leth cudromach, thathas a’ cleachdadh àireamh mhòr de phìoban tonn siubhail, magnetrons, tiùban ruith, tiùban tonn ruith, gyrotrons agus innealan falamh dealain eile, agus bidh magnets SmCo a’ dèanamh giùlan dealanach air feadh an t-slighe òrdaichte.

5. SmCo magnetic extractors ann an tobraichean domhainn fo 3000 meatair, agus SmCo magnetach drive (pump) ann an àrd Teòthachd àrainneachd de 200 ℃.

6. Ceann suidse magnetach, dealaiche magnetach, giùlan magnetach, NMR, msaa.

Liosta ìrean magnet SmCo

| Stuth | No | Br | Hcb | Hcj | (BH) as àirde | TC | TW | (Br) | Hcj | ||||

| T | |KGs | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | ℃ | ℃ | % ℃ | % ℃ | ||

| 1:5 SmCo5 (Smpr)Co5 | YX-16 | 0.81-0.85 | 8.1-8.5 | 620-660 | 7.8-8.3 | 1194-1830 | 15-23 | 110-127 | 14-16 | 750 | 250 | -0.050 | -0.30 |

| YX-18 | 0.85-0.90 | 8.5-9.0 | 660-700 | 8.3-88 | 1194-1830 | 15-23 | 127-143 | 16-18 | 750 | 250 | -0.050 | -0.30 | |

| YX-20 | 0.90-0.d4 | 9.0-9.4 | 676-725 | 8.5-9.1 | 1194-1830 | 15-23 | 150-167 | 19-21 | 750 | 250 | -0.050 | -0.30 | |

| YX-22 | 0.92-0.96 | 9.2-9.6 | 710-748 | 8.9-94 | 1194-1830 | 15-23 | 160-175 | 20-22 | 750 | 250 | -0.050 | -0.30 | |

| YX-24 | 0.96-1.00 | 9.6-10.0 | 730-770 | 9.2-9.7 | 1194-1830 | 15-23 | 175-190 | 22-24 | 750 | 250 | -0.050 | -0.30 | |

| 1:5 SmCo5 | YX-16S | 0.79-0.84 | 7.9-8.4 | 612-660 | 7.7-83 | ≥ 1830 | ≥23 | 118-135 | 15-17 | 750 | 250 | -0.035 | -0.28 |

| YX-18S | 0.84-0.89 | 8.4-89 | 644-692 | 8.1-8.7 | ≥ 1830 | ≥23 | 135-151 | 17-19 | 750 | 250 | -0.040 | -0.28 | |

| YX-20S | 0.89-0.93 | 8.9-9.3 | 684-732 | 8.6-92 | ≥ 1830 | ≥23 | 150-167 | 19-21 | 750 | 250 | -0.045 | -0.28 | |

| YX-22S | 0.92-0.96 | 9.2-9.6 | 710-756 | 8.9-95 | ≥ 1830 | ≥23 | 167-183 | 21-23 | 750 | 250 | -0.045 | -0.28 | |

| YX-24S | 0.96-1.00 | 9.6-10.0 | 740-788 | 9.3-9.9 | ≥ 1830 | ≥23 | 183-199 | 23-25 | 750 | 250 | -0.045 | -0.28 | |

| 1:5 (SmGd)Co5 | LTc(YX-10) | 0.62-0.66 | 62-6.6 | 485-517 | 6.1-6.5 | ≥ 1830 | ≥23 | 75-8A | 9.5-11 | 750 | 300 | 20-100 ℃ +0.0156% ℃ 100-200 ℃ +0.0087% ℃ 200-300 ℃ +0.0007% ℃ | |

| Ce(CoFeCu)5 | YX-12 | 0.7Q-0.74 | 7.0-7.4 | 358-390 | 4.5-4.9 | 358-478 | 4.5-6 | 80-103 | 10-13 | 450 | 200 | ||

| Sm2 (CoFeCuZr)17 | YXG-24H | 0.95-1.02 | 9.5-10.2 | 692-764 | 8.7-9.6 | ≥ 1990 | ≥25 | 175-191 | 22-24 | 800 | 350 | -0.025 | -0.20 |

| YXG-26H | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥ 1990 | ≥25 | 191-207 | 24-26 | 800 | 350 | -0.030 | -0.20 | |

| YXG-28H | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥ 1990 | ≥25 | 207-220 | 26-28 | 800 | 350 | -0.035 | -0.20 | |

| YXG-30H | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥ 1990 | ≥25 | 220-240 | 28-30 | 800 | 350 | -0.035 | -0.20 | |

| YXG-32H | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥ 1990 | ≥25 | 230-255 | 29-32 | 800 | 350 | -0.035 | -0.20 | |

| YXG-22 | 0.93-0.97 | 9.3-97 | 676-740 | 8.5-93 | ≥ 1453 | ≥ 18 | 160-183 | 20-23 | 800 | 300 | -0.020 | -0.20 | |

| YXG-24 | 0.95-1.02 | 9.5-10.2 | 692-764 | 87-9.6 | ≥ 1433 | ≥ 18 | 175-191 | 22-24 | 800 | 300 | -0.025 | -0.20 | |

| YXG-26 | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥ 1433 | ≥ 18 | 191-207 | 24-26 | 800 | 300 | -0.030 | -0.20 | |

| YXG-28 | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥ 1433 | ≥ 18 | 207-220 | 26-28 | 800 | 300 | -0.035 | -0.20 | |

| YXG-30 | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥ 1453 | ≥ 18 | 220-240 | 28-30 | 800 | 300 | -0.035 | -0.20 | |

| YXG-32 | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥ 1433 | ≥ 18 | 230-255 | 29-32 | 800 | 300 | -0.035 | -0.20 | |

| YXG-26M | 1.02-1.05 | 10.2-10.5 | 676-780 | 8.5-9.8 | 955-1433 | 12-18 | 191-207 | 24-26 | 800 | 300 | -0.035 | -0.20 | |

| YXG-28M | 1.03-1.08 | 10.3-10.8 | 676-796 | 8.5-10.0 | 955-1433 | 12-18 | 207-220 | 26-28 | 800 | 300 | -0.035 | -0.20 | |

| YXG-30M | 1.08-1.10 | 10.8-11.0 | 676-835 | 8.5-10.5 | 955-1433 | 12-18 | 220-240 | 28-30 | 800 | 300 | -0.035 | -0.20 | |

| YXG-32M | 1.10-1.13 | 11.0-11.3 | 676-852 | 8.5-10.7 | 955-1433 | 12-18 | 230-255 | 29-32 | 800 | 300 | -0.035 | -0.20 | |

| YXG-24L | 0.95-1.02 | 9.5-10.2 | 541-716 | 6.8-9.0 | 636-955 | 8-12 | 175-191 | 22-24 | 800 | 250 | -0.025 | -0.20 | |

| YXG-26L | 1.02-1.05 | 10.2-10.5 | 541-748 | 6.8-9.4 | 636-955 | 8-12 | 191-207 | 24-26 | 800 | 250 | -0.035 | -0.20 | |

| YXG-28L | 1.03-1.08 | 10.3-10.8 | 541-764 | 6.8-9.6 | 636-955 | 8-12 | 207-220 | 26-28 | 800 | 250 | -0.035 | -0.20 | |

| YXG-30L | 1.08-1.15 | 10.8-11.5 | 541-796 | 6.8-10.0 | 636-955 | 8-12 | 220-240 | 28-30 | 800 | 250 | -0.035 | -0.20 | |

| YXG-32L | 1.10-1.15 | 11.0-11.5 | 541-812 | 6.8-10.2 | 636-955 | 8-12 | 230-255 | 29-32 | 800 | 250 | -0.035 | -0.20 | |

| (SmEr)2(CoTM)17 | LTC (YXG-22) | 0,94-0,98 | 9.4-9.8 | 668-716 | 8.4-9.0 | ≥1433 | ≥18 | 167-183 | 21-23 | 840 | 300 | -50-25 ℃ +0.005% ℃ 20-100 ℃ -0.008% ℃ 100-200 ℃ -0.008% ℃ 200-300 ℃ -0.011% ℃ | |

| Feartan corporra Samarium Cobalt | ||

| Paramadair | SmCo 1:5 | SmCo 2:17 |

| Teòthachd curie ( ℃) | 750 | 800 |

| Teòthachd obrachaidh as àirde ( ℃ | 250 | 300 |

| Hv(MPa) | 450-500 | 550-600 |

| Dùmhlachd(g/cm³) | 8.3 | 8.4 |

| Co-èifeachd teòthachd Br (% / ℃) | -0.05 | -0.035 |

| Co-èifeachd teòthachd iHc (% / ℃) | -0.3 | -0.2 |

| Neart tensile (N / mm) | 400 | 350 |

| Neart briseadh transverse (N / mm) | 150-180 | 130-150 |

Iarrtas

Tha magnet SmCo air a chleachdadh gu farsaing ann an aerospace, motair dìon-teodhachd àrd, uidheamachd microwave, conaltradh, uidheamachd meidigeach, ionnstramaidean agus meatairean, diofar uidheamachd tar-chuir magnetach, mothachairean, pròiseasairean magnetach, motaran coil guth agus mar sin air adhart.

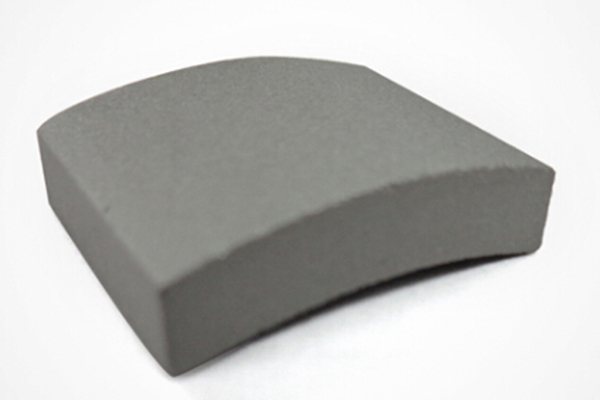

Taisbeanadh dealbh

-

Segment NdFeB, mar as trice air a chuir an sàs ann an dealan ...

-

Round NdFeb, mar as trice air a chuir an sàs ann an electroacou ...

-

Diofar mheudan de magnet rubair / duilleag magnet

-

Cumaidhean eile NdFeB, leithid cumadh arain, toll-s...

-

Ring NdFeB, mar as trice air a chleachdadh ann an glaodhaire

-

Co-chruinneachaidhean Magnet le NdFeB, SmCo, AlNiCo agus ...